The argument against increasing paperwork!

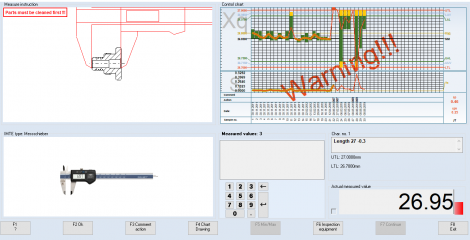

CAQ (Computer-aided Quality Assurance) is a comprehensive quality management system featuring graphic interactive inspection and quality assurance. It makes the live much easier for

companies in the medical, the aircraft and the automotive industry. Traceability is consequently implemented. CAQ software audits become a mere formality.

companies in the medical, the aircraft and the automotive industry. Traceability is consequently implemented. CAQ software audits become a mere formality.