Machine without network interface

Information such as "machine running" or the number of pieces produced can be collected most cost-effectively via an IO module.

With an M command in the NC program a signal output can be activated. In this way pieces can be countet. The signal outputs are connected to the inputs of an IO module. The IO module has several digital 24V inputs, some of them can be configured as counters. In addition, the IO module has an Ethernet interface and delivers the data to a central server. In principle, this is a cost-effective and simple solution for all machine and the machine is not directly connected to the company network.

Machine with network interface

For about 15 years, most machines tools have been equipped with a network interface. Unfortunately it is by no way that machine data can simply be obtained via this interface. The machine tool and cnc control manufacturers must explicitly offer this possibility. Or in other words, the buyer of such machines often has to buy this explicitly as an option.

Sometimes a quick look at the purchase contract or a call to the supplier is sufficient to know whether the existing machine offers this option. But beyond that, it can also be tested on site with the right tools.

Since almost no machine and no control are the same, the machine connection is largely a matter of experience. A competent MDC provider is characterised by the fact that he gets the required data from the machine with as little effort as possible.

Already at the time of purchase, make sure that the machine has a defined interface for data exchange! Preferably, it should be OPC UA. OPC UA is common and seems to be establishing itself as the standard for both, cnc machine tool manufacturers and MDC providers.

OPC UA, MTConnect, MQTT, FOCAS2, Euromap etc.

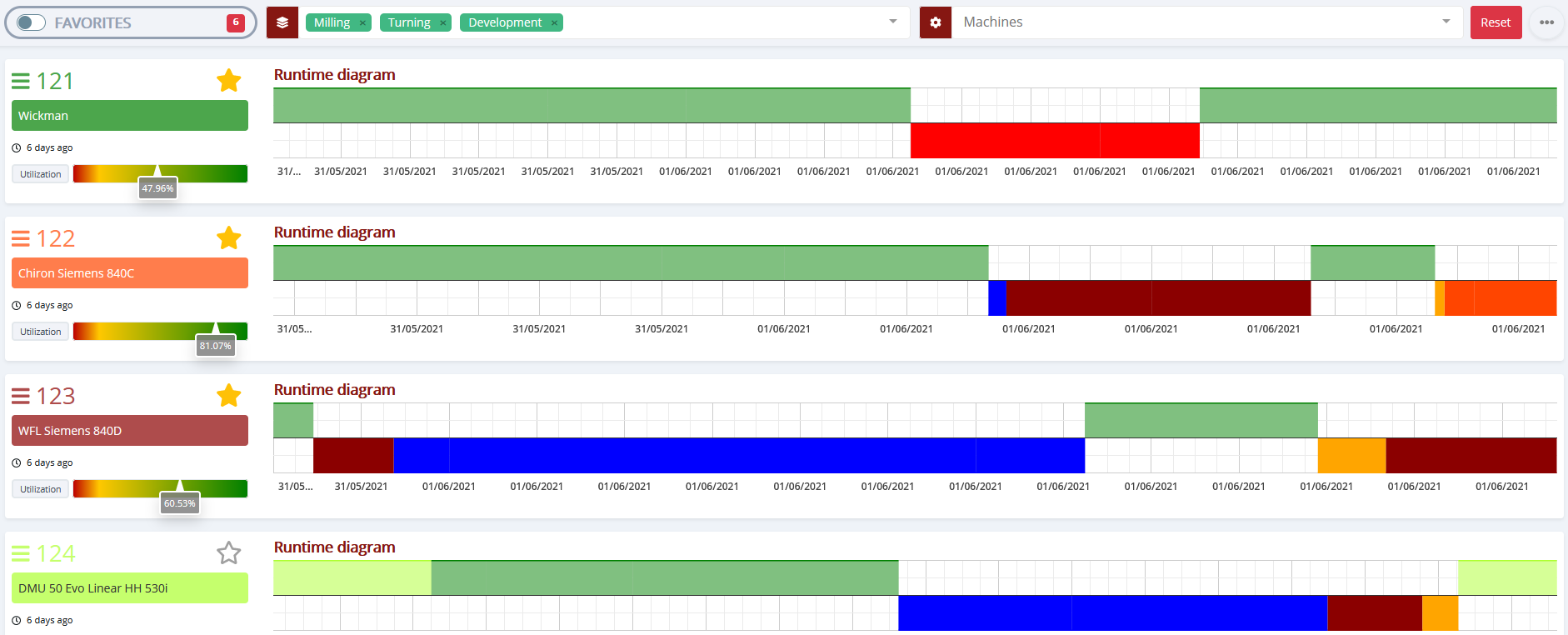

A standard interface such as OPC UA, MTConnect or MQTT facilitates the direct readout of data from a controller. A wide variety of data can be recorded and evaluated:

- Execution state

- Controller mode

- Machine on stand-by

- Part count

- Spindle RPM

- Spindle override (%)

- Feed rate

- Feed rate override (%)

- Tool number

- Program number

- Program comment

- Etc.

Quinx AG can directly connect machine tools. With simple on-site tests, we check where this is possible without the support of the machine manufacturer. Interested?

IT security

In the case of direct integration of systems into the company LAN, particular attention must be paid to IT security. Machine controls usually have no virus protection. They are generally poorly protected or not protected at all against attacks. Quinx AG supports various approaches to protecting the controllers. Contact us for further information!