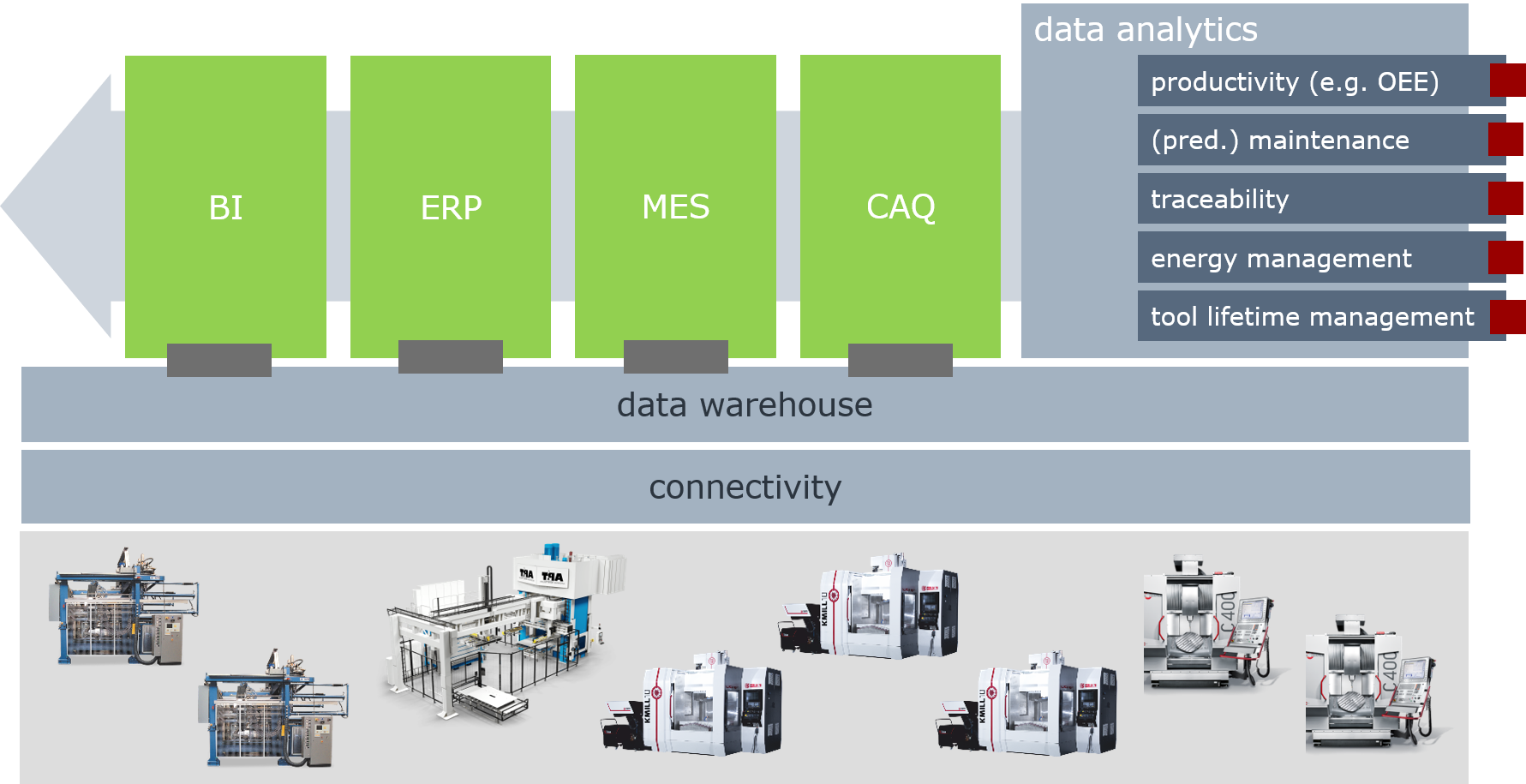

Quinx MDC 4000 analyses the collected production data to calculate the OEE of each system.

QMIP records the production process persistently: Which part was produced with which program on which plant by whom. This is an essential aspect in traceability. In the meantime, a large number of companies have to provide this evidence.

If a system has the necessary sensors, the energy consumption per produced part can be calculated. Energy efficiency is becoming increasingly important. It has a direct influence on the CO2 balance of a company.

Preventive maintenance prevents systems from stopping at the worst possible moment. If maintenance intervals are shorter than necessary, valuable production time is wasted. Therefore Quinx optimises maintenance intervals based on real production and process data. Preventive maintenance interventions are displayed in JOBDISPO production planning and are taken into account when planning customer orders.

Tool costs are a significant cost factor. With the Tool Lifetime Management module, Quinx can evaluate tool lifetime and monitor tool abrasion.